-

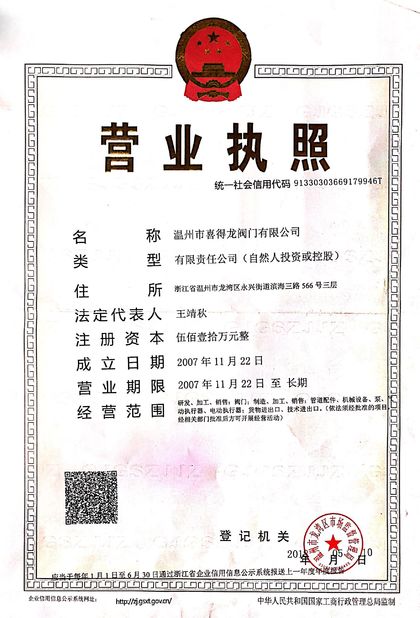

Standard: Business LicenseNumber:Issue Date:Expiry Date:

-

Standard: ISO9001:2015Number:Issue Date:Expiry Date:

-

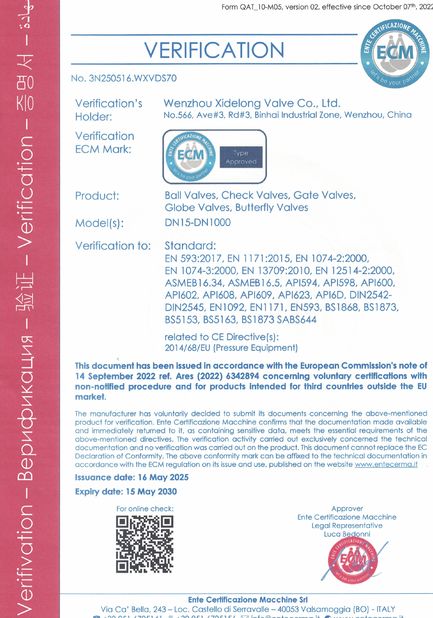

Standard: CE CertificationNumber:Issue Date:Expiry Date:

-

Standard: DAS CertificationNumber:Issue Date:Expiry Date:

-

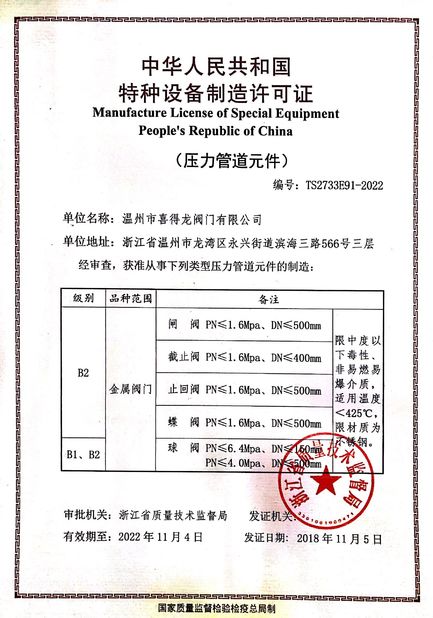

Standard: Manufacture License of Spencial EquipmentNumber:Issue Date:Expiry Date:

-

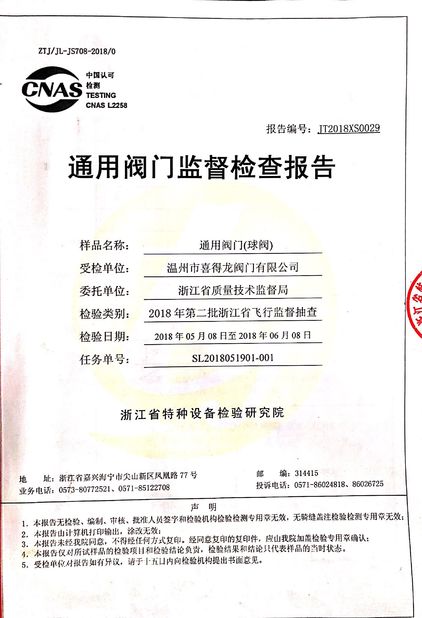

Standard: Supervision Inspection Report Of General ValveNumber:Issue Date:Expiry Date:

-

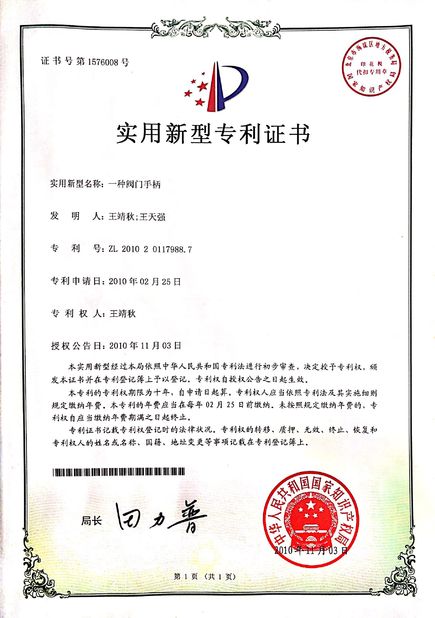

Standard: Certificate of Utility Model Patent For a Valve HandleNumber:Issue Date:Expiry Date:

-

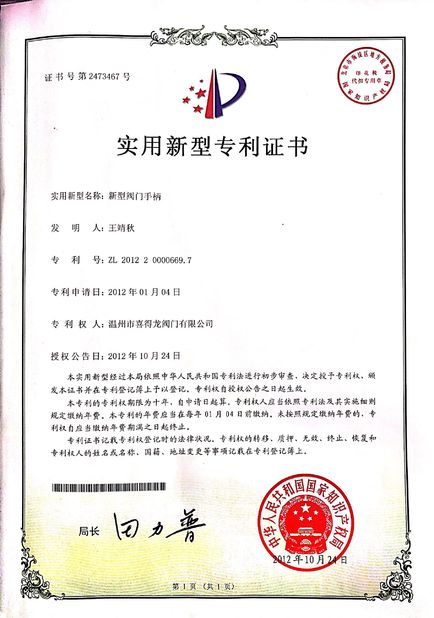

Standard: Certificate of Utility Model Patent For New Type Valve HandleNumber:Issue Date:Expiry Date:

-

Standard: Certificate of Design PatentNumber:Issue Date:Expiry Date:

-

Standard: CE CertificationNumber:Issue Date:Expiry Date:

Improving product quality is the guarantee of premise and development for Business survival. Product quality is a key factor for enterprises to win in the market competition. Enterprises can develop new markets, seek new opportunities, and provide broad prospects for the further development of enterprises as we have the pass of high quality products!

1. The most basic quality inspection

Our company has set up a quality inspection department. The staff members need to pass training and assessment, and require an understanding of the inspection specifications and standards. They can accurately determine whether the product quality is qualified, and can give a simple analysis and interpretation of the quality results so that the production department is targeted to correct and can improves the products' quality and appearance.

2. Continuously strengthen employees' awareness of high quality products

Managers visit the workshops irregularly to observe the existing work processes of the products to reduce work errors, improve work efficiency, and continuously improve the quality awareness of all employees!

3. Equipment maintenance

Our company has formulated the "Equipment Management System", which has clear regulations on equipment purchase, circulation and maintenance and is constantly improving.

Maintenance equipment by Quality Inspection Department once every quarter, so that each equipment can work smoothly and export each batch of goods on time.

4. Production materials

Our company has a purchasing department. In addition to the regular requirements such as quantity, weight, unit price and delivery date, all technical indicators need to meet the quality testing standards.

5. Production environment

The production environment is kept clean, materials, tooling, fixtures are neat and orderly, and every week management personnel will check the relevant departments irregularly.Ensure that employees can work efficiently in a good environment.

6. Standardization of quality system

The management personnel compiled and reviewed the ISO9001 and CE system documents of the leading company, and incorporated the above three points of control work into the overall plan of the company's quality system improvement. On the basis of the relevant standards, the continuous improvement and continuous circulation were carried out. Thereby achieving continuous improvement of the entire quality system.

7. After sales service

The sales department is responsible for handling customer complaints and complaints, and responding to customers within 24 hours, through telephone communication, mailings, and visiting customers, to negotiate with customers on controversial quality issues and reach a consensus.